Notes on electrode steam humidification

Observe water quality!

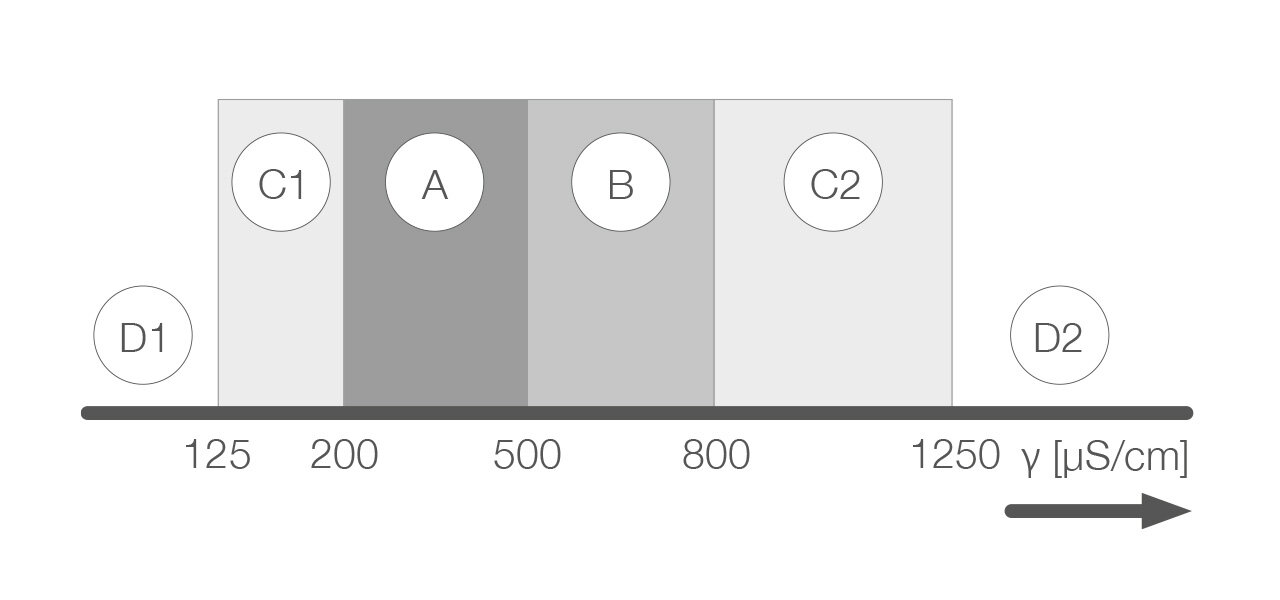

D1: Range below the operating limit

C1: Range of low conductivity

A: Range of normal conductivity

B: Range of increased conductivity

C2: Range of high conductivity

D2: Range above the operating limit

Avoid condensation as far as possible and minimise counterpressure!

- Few deflections

- Make wide bends

- Appropriately large pipe cross-sections

- Short hoses

- Insulated fixed piping is preferred

- Steam pipes should be laid with a gradient of 5 - 10%

Notes on heater type steam humidification

Observe water quality!

- Ideal demineralised water or at least softened

- Conductivity > 3 µS/cm

- Low total hardness

Avoid condensation as far as possible and minimise counterpressure!

- Few deflections

- Make wide bends

- Appropriately large pipe cross-sections

- Short hoses

- Insulated fixed piping is preferred

- Steam pipes should be laid with a gradient of 5 - 10%

Notes on gas steam humidification

Observe water quality!

- Ideal demineralised water or at least softened

- Conductivity > 3 µS/cm

- Low total hardness

Avoid condensation as far as possible and minimise counterpressure!

- Few deflections

- Make wide bends

- Appropriately large pipe cross-sections

- Short hoses

- Insulated fixed piping is preferred

- Steam pipes should be laid with a gradient of 5 - 10%

Notes on the spray nozzle system

Observe water quality!

- Demineralised 5 to 50 µS/cm

- Optimum temperature < 15 °C

- Dynamic flow pressure > 1 bar,

optimal > 2 bar

Air flow between 1.0 - 2.8 m/s input conditions!

- If possible, use enthalpy control

- The higher the inlet temperature and the lower the outlet humidity, the higher the efficiency